Aerofoundry is an Aeronautics Design House. We specialize on aircraft design and manufacturing, from concept to flight. Aeronautics Engineering is in our DNA.

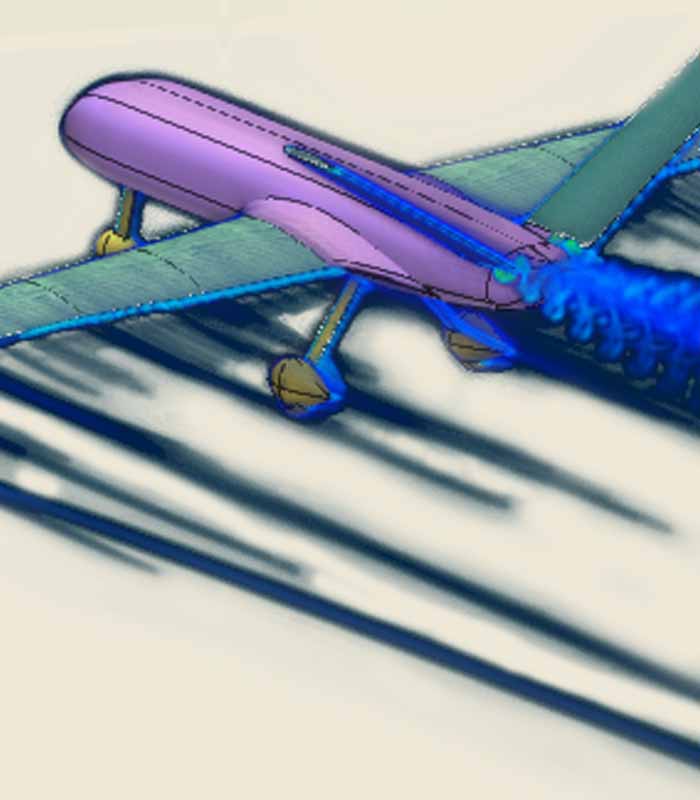

Our advanced platforms are designed following a multidisciplinary method, attaining the best aerodynamic and structural efficiency for the conceptual predefined constraints. We offer performance, fuel efficiency, easier payload integration, flexible operation, and cost-efficient maintenance and support.

Our Engineering Department can integrate your selected payload into our airframes, or we can support your payload integration work, including testing and validation. Or you can choose from several off-the-shelf payload implementations we have available, already validated by our engineers to address the most frequent applications.

Our aerial platforms are designed as Open Aircraft Frameworks (OAF) capable of carrying a wide arrange of payload configurations, customized to our customer’s requirements.

Our OAF span from (1) a tailsitter, with swappable payload nose cartridges, for single-operator use, or (2) a tactical hand-launched long-endurance fixed-wing 10kg model, (3) a 25kg light long-endurance plane, through (4) an advanced tactical fast Class II/III aircraft, to (5) an innovative vertical takeoff/landing, tandem tilt-wing design with a hybrid-electric powerplant.

All OAF are designed for easy integration with a wide spectrum of avionics, autopilots, and payload. But, if those airframes are not enough, we have more than 20 alternative airframe designs, tested and validated, from where you can choose for a more personalized solution.

We work for payload integrators selling unmanned solutions on top of our proven airframes.

All OAF are designed for easy integration with a wide spectrum of avionics, autopilots, and payload. However, if those airframes are not enough to choose from, we have more than 20 alternative airframe designs, tested and validated, from where you can setup a more personalized solution.

We supply our airframes as ready-to-fly aerial platforms for those integrators to setup their configurations (where we certify the integration’s safety, giving warranty to the aircraft with that payload).

When airframe modifications are required to address specific integration requirements, our Engineering Department can produce a solution for you in an amenable timeframe, as our state-of-the-art prototyping lab can fast produce, test, and validate the modified aircraft. Then, even production in small quantities is possible, with the digitally controlled manufacturing pipeline, from plug and mold, to airframe vacuuming, oven curing, and paint, all in a smooth flow, following the highest quality standards, in a tight schedule.

When a solution is produced on top of one of our airframes, an OEM contract is signed where the customized package (IP) is owned by the customer, gaining the right of adding its trademarks and logos.

Aerofoundry maintains manufacturing facilities strategically distributed regionally to ensure cost optimization, and reduced testing and validation restrictions, and minimal export controls.

We offer our capabilities to other companies, on a contract basis, to manufacture aircraft fully designed by them, at a very competitive cost, with very high quality. Our work is Brazilian level quality, one of the best in the World.

We ensure that your aircraft design is safe and secured in our hands, and that the final product will fulfill your highest expectations.

Our machinery is designed and built in-house, specifically for aircraft manufacturing (capabilities, dimensions, and precision). Some are even dimensioned specifically to our aircraft models.

In the same way, our manufacturing facilities are designed following standardized layouts, with our custom-made machines, which are easy to replicate anywhere in the World. We can even fabricate the machinery locally.

Then, if a customer requires it, it is relatively easy for us to setup manufacturing facilities to produce one or several our airframe models. In that case, we set up a factory tailored for the specified monthly quantities, and give training in production, assembly, quality control, integration of avionics, and flight validation for each unit produced.

When we encounter a scenario where our OAF or alternative aircraft projects are not the most adequate, we can design new airframes from scratch, following your specifications, adding shapes originality to facilitate your branding efforts, within budget constraints.

When a new airframe is designed for a specific customer, the IP is transferred to the customer.

We manufacturing the airframe, or set up a factory for you.